From Reactive Buying to Proactive Market Engagement

Constantly reacting to supply chain disruptions leads to higher costs and wasted time. This post breaks down how to move toward proactive market engagement by using predictive data and building stronger supplier relationships. Learn how a shift in strategy can help your procurement team stay ahead of market shifts and drive better results.

From Reactive Buying to Proactive Market Engagement

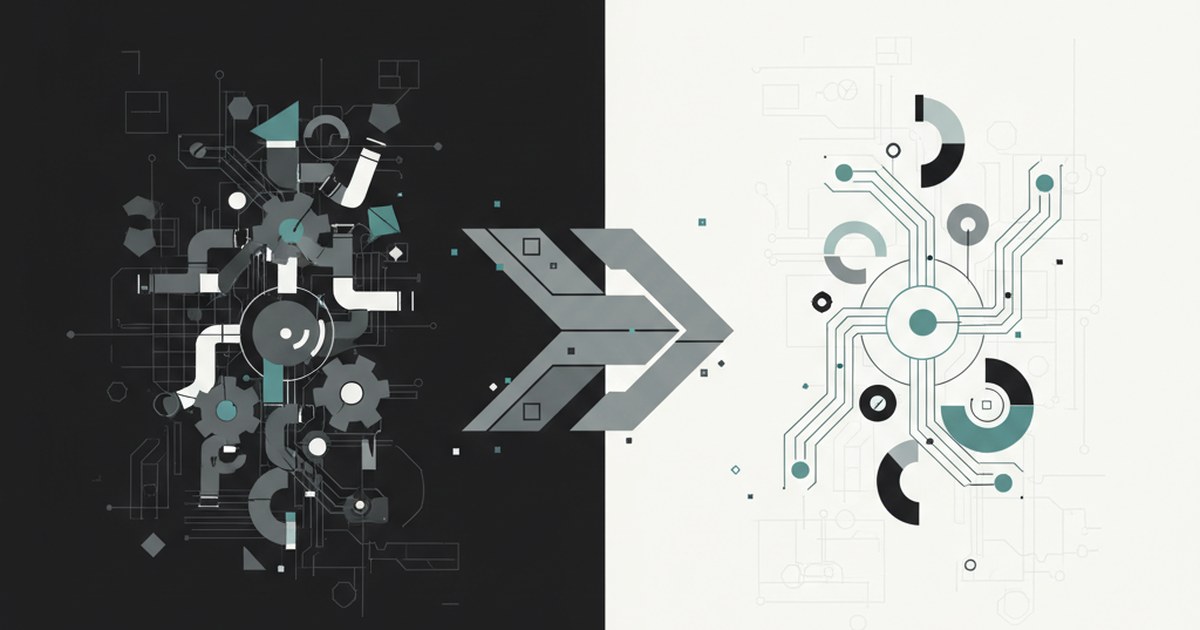

In today’s fast-paced and ever-changing market climate, procurement and supply chain leaders face pressure like never before. With global disruptions, fluctuating demand, and increased competition, many organizations find themselves trapped in a cycle of reactive buying. When faced with urgent needs, they often prioritize short-term fixes rather than long-term solutions. This reactive approach can lead to inefficiencies, inflated costs, and lost opportunities. So, how can procurement and supply chain executives break free from this cycle and shift toward proactive market engagement? Let’s explore the strategies that can transform an organization’s approach to procurement.Understanding the Reactive Buying Cycle

Before diving into solutions, it’s essential to recognize the characteristics of reactive buying. This approach typically includes hastily sourcing materials or services in response to immediate demands without a comprehensive strategy. For example, consider a manufacturing company that suddenly experiences a surge in demand for one of its products due to seasonal trends. Instead of proactively negotiating contracts with suppliers beforehand, they scramble to obtain materials, often at inflated prices. This scenario illustrates the pitfalls of a reactive strategy, where companies are forced to settle for suboptimal terms and may even compromise on quality. The first step toward transformation is a conscious acknowledgment of these patterns. By understanding the cycle of reactive buying, leaders can initiate a fundamental shift necessary for sustainable growth.Crafting a Proactive Procurement Strategy

To transcend reactive buying, organizations need to adopt a proactive procurement strategy. This involves anticipating future needs, understanding market dynamics, and fostering strong supplier relationships. One effective approach is the use of predictive analytics. By leveraging data analytics to anticipate trends, organizations can better forecast demand and adjust their procurement strategies accordingly. For instance, a food manufacturer can utilize historical sales data to predict peak seasons, enabling them to negotiate better contracts with suppliers ahead of time. This proactive stance not only ensures that they have access to necessary materials but often allows for cost savings and enhanced supplier relationships. Another aspect of this proactive approach is fostering collaboration with suppliers. Engaging in open dialogues with suppliers can help organizations identify potential risks and opportunities early on. For instance, tech companies that collaborate closely with component manufacturers can gain insights into raw material availability and can plan their purchasing strategies accordingly. By strengthening these relationships, organizations can often secure better prices and terms, while also unlocking innovation opportunities that can lead to competitive advantages.Implementing a Market Engagement Framework

Market engagement goes beyond traditional supplier calls and contract negotiations. A robust market engagement framework compels leaders to actively participate in shaping the supply landscape. At the core of effective market engagement is understanding market dynamics and competition. Procurement leaders must continually assess the economic environment, technology developments, and regulatory changes that can affect supply chains. For example, during the early onset of the COVID-19 pandemic, companies with robust market engagement frameworks were better positioned to pivot their strategies. Many organizations that monitored market signals swiftly engaged alternative suppliers, secured additional inventory, or even diversified their product offerings. This agility not only ensured continuity but also allowed companies to emerge from the crisis stronger than their competitors. Additionally, investing in technology can significantly enhance market engagement. Digital platforms that offer real-time market insights empower procurement teams to make informed decisions quickly. Fleet management firms, for example, can utilize telematics data to not only optimize routes but also manage fuel costs and maintenance schedules proactively, ultimately leading to significant cost efficiency.Continuous Learning and Flexibility

To maintain a proactive stance in procurement, continuous learning and adaptability are vital. The business is not static, and market conditions are ever-evolving. Leaders should encourage a culture of ongoing training and upskilling within their teams to stay ahead of industry trends and emerging technologies. Consider a construction firm that implements regular training sessions on the latest material advancements and sustainability practices. By doing so, they equip their procurement team with knowledge that enhances decision-making and encourages innovative sourcing strategies. This culture of continuous improvement keeps procurement practices agile and responsive to both market changes and organizational goals. Moreover, engaging with industry networks and professional organizations allows leaders to learn from peers and share best practices. This kind of engagement opens doors to new opportunities and partnerships that can add value to their supply chains. For instance, a packaging company participating in industry roundtables may gain insights into sustainable materials that not only meet compliance but also resonate with their customers' eco-friendly demands.Measuring Success through Outcomes

Transitioning from reactive buying to proactive market engagement is not an overnight endeavor, but the metrics of success are worth pursuing. Organizations can measure the progress of this transformation through various Key Performance Indicators (KPIs): 1.Cost Savings:

Evaluating the savings achieved through strategic sourcing contracts compared to the previous reactive buying practices demonstrate financial improvements. 2.Supplier Relationships:

Assessing supplier performance and satisfaction can indicate the strength of partnerships established through proactive engagement. 3.Lead Times:

Monitoring reductions in lead times showcases improved efficiency and planning in procurement cycles. 4.Market Adaptability:

Tracking the ability to pivot in response to market changes can reflect the agility of the procurement strategy. In conclusion, breaking the cycle of reactive buying and fostering a culture of proactive market engagement may initially require a mindset shift, but the measurable business outcomes are substantial. By developing a proactive procurement strategy, implementing a robust market engagement framework, encouraging continuous learning, and measuring success through tangible outcomes, procurement leaders can position their organizations for long-term success. As a result, they will not only mitigate risks but also unlock new opportunities in an increasingly competitive marketplace. By making this strategic transition, procurement becomes a critical driver of business success, crafting a resilient and adaptive supply chain for the future.

Grow with Purchaser

Ready to resolve your sourcing bottlenecks?

Purchaser helps you identify and eliminate supply chain delays while streamlining your entire procurement process.

Join leading companies optimizing their supply chain.